Material Handling Case for JEWERET

Automation of Order Process

Introduction

JéWéRET specialises in do-it-yourself (DIY) products for applications in house construction and interior decorating. A part of these products is manufactured at their own JéWéRET manufacturing plant. The products supplied by JéWéRET to the DIY trade include floors, closet interiors and made to measure sliding doors, mouldings, planed and rough timber, wall and ceiling products and decorative products. Great knowledge of the market and excellent contacts with reputable manufacturers enable JéWéRET to purchase products both fast and advantageously – from complete shiploads to smaller specialist orders. Its wide-ranging experience with a great variety of materials, the worldwide purchasing of products, combined with its own production at the JéWé Houtwarenfabriek (Sawmill factory) plant; all these combine to give JéWéRET a great advantage with respect to stock management.

Objective

JéWéRET has a great diversity of products from which clients (DIY) can order. JéWéRET wanted to automate the order pick process of its products. The orders are currently manually picked, which is a time consuming process. JéWéRET has consulted Smart Warehouse Design and Talumis to support them in this process. The objective was to develop concepts for the automation process, analyze its performance by means of simulation models and determine the best concept for JéWéRET.

Solution

Smart Warehouse Design determined the 250 most ordered products from JéWéRet by means of analyzing various production days. These products are stocked in a storage area from which can be picked by cranes to form a delivery unit. A delivery unit is a stack of products which have certain restrictions in stacking order. The different production days are also used to estimate peak order days for which the different concepts needed to be analyzed.

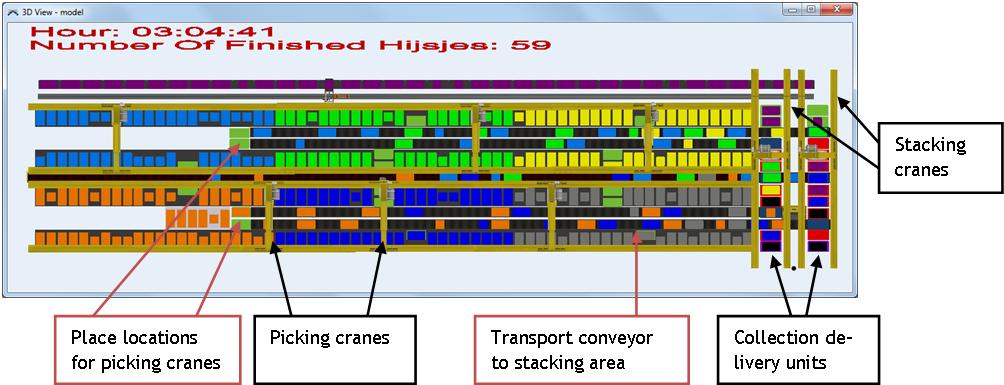

TALUMIS constructed, in close cooperation with Smart Warehouse Design and JéWéRET the simulation models for the different concepts. Concept development was an iterative process. In the first stage the delivery units were located on a fixed position at the right side of the storage area. Products were picked up by one of the 6 picking cranes and transported to stacking area. Initially two stacking cranes were considered. For both the top and the bottom part of the stack two conveyors lead the products to the corresponding stacking crane.

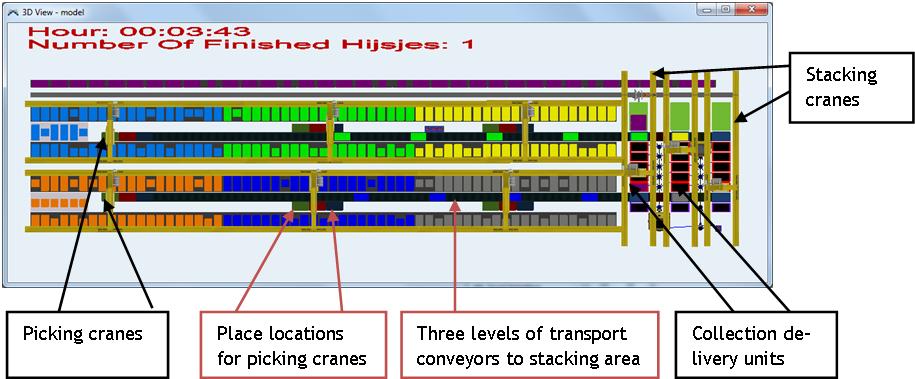

As the required output was not reached a second concept was created based on the knowledge and bottle-necks of the first layout. To achieve the output an extra stacking crane was needed. Simultaneously this resulted in the need for three conveyors for both upper and lower side of the storage area to be able to connect every product with every delivery unit stacking location. These three conveyors were placed above each other on three different levels and for each area and conveyor a place location (entry to conveyor) was created

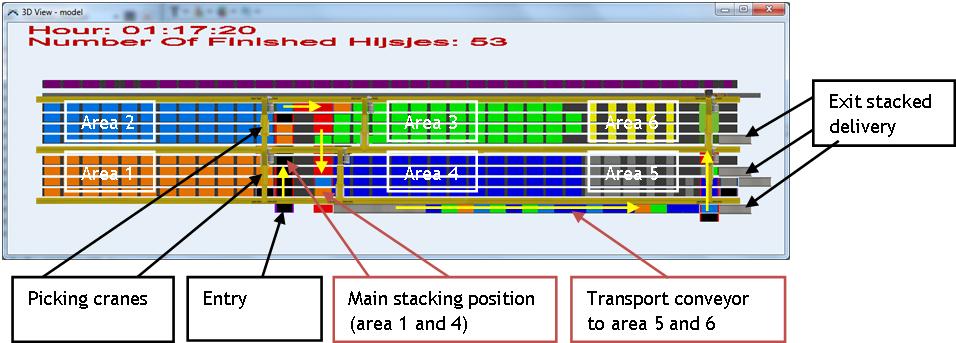

During the optimization process the layouts were continuously evaluated with the possible suppliers of the needed equipment. Each supplier has different possibilities for handling the products. This continuous evaluation resulted in a different concept where the products were not brought to the stacking location, but the delivery unit is transported through the different areas as is depicted below. In each area one main stacking location exists where products are stacked for this area (if needed). In each area an extra buffer position exists for high volume orders for this area to keep the picking crane occupied as much as possible. This new concepts completely eliminates the need for the stacking area.

Results

This project is a clear example of how simulation is used as a decision support tool. It was a cooperation between JéWéRET, Smart Warehouse Design, Talumis and equipment suppliers to develop the best concept suited for automation of the order process for JéWéRET. In the end a layout resulted which performed best for the output, with less equipment and had the most robust behavior. If the first designed concept would have been compared with the final layout an estimated savings could be quantified of around €1.000.000!