The benefits of a good plan

Fit-for-purpose planning and scheduling software will increase profitability to your business. A good plan or schedule will result in better revenue as recourses are better utilized and synchronized. There are huge profits to be made if plans and schedules can be improved. There are many approaches to create plans and schedules and most involve referring to it as creating an “optimized plan”. This means that the process involves solving (or optimizing) a certain mathematical model. Though the answer to the mathematical model might be optimal (or near optimal in more complex models), the solution is often far from optimal when executing the plan in real life. This is because in real life there is both uncertainty and the actual processes are more complex than the mathematical model tries to mimic.

Simulation based scheduling

An alternative approach to mathematical optimization, is using ‘simulation based scheduling’ or ‘simulation assisted scheduling’. This process involves creating a detailed model of the system and implement heuristic rules for prioritizing certain orders over others. By ‘running’ the model and logging the result a possible schedule is created. The advantage is that the simulation model is more accurate than mathematical models. But downside on a pure simulation based approach is that decisions are taken based on the state of the simulation model; a simulation model cannot use a look-ahead approach like a mathematical model can.

Dirk-Jan Moens

Owner / Oil, Gas & Chemicals Consultant

Ask Dirk-Jan a question

TalumisAsk Dirk-Jan a question

Best of both worlds: a Digital Twin combining Simulation & Optimization

At Talumis we create ‘best-of-both-worlds’ solutions. By integrating mathematical and simulation models within our Digital Twin software, better and more robust schedules are created. This can either be done by improving and fine-tuning mathematical models or by combining simulation based scheduling and mathematical optimization to create plans and schedules. By simulating schedules in a stochastic real-life environment, we are also able to prove and test that the Talumis’ solution created is the best solution for your problem.

As there will always be exceptions in real life or information that is not part of a model, we also allow users to manually change schedules. The new schedule or plan can then be tested and verified again by using the simulation model. Therefore all Talumis ‘planning and scheduling software solutions incorporate both simulation and optimization methods.

..or look at an example video

Planning & Scheduling Software

If you want to learn more about how Talumis can help with setting up planning and scheduling solutions, have a look at our advanced planning and Digital Twin platform TraverseBoard.

Talumis industry specific solutions

Talumis created planning and scheduling solutions for various industries. We believe that different problems result in different solutions; there is not a solution that is useful in all types of systems.

Shell

For LNG (liquefied natural gas) supply chain planning and scheduling a solution has been developed that can create and optimize annual delivery plans. The optimization takes into account future uncertainties like weather events and unscheduled production outages. The resulting plan is both robust (can recover from unforeseen events) and optimal (uses the best delivery strategy based on revenue).

ESI-Eurosilo

Another example is the on-line monitoring and control of coal storage and burn plan in a power plant. The simulation model calculates, based on on-line (real-time) PLC information, where particular coal qualities are located in the storage facility. Then a simple algorithm is used to create the best short-term burning mix and plan. This plan can than also be simulated to validate the calculated plan.

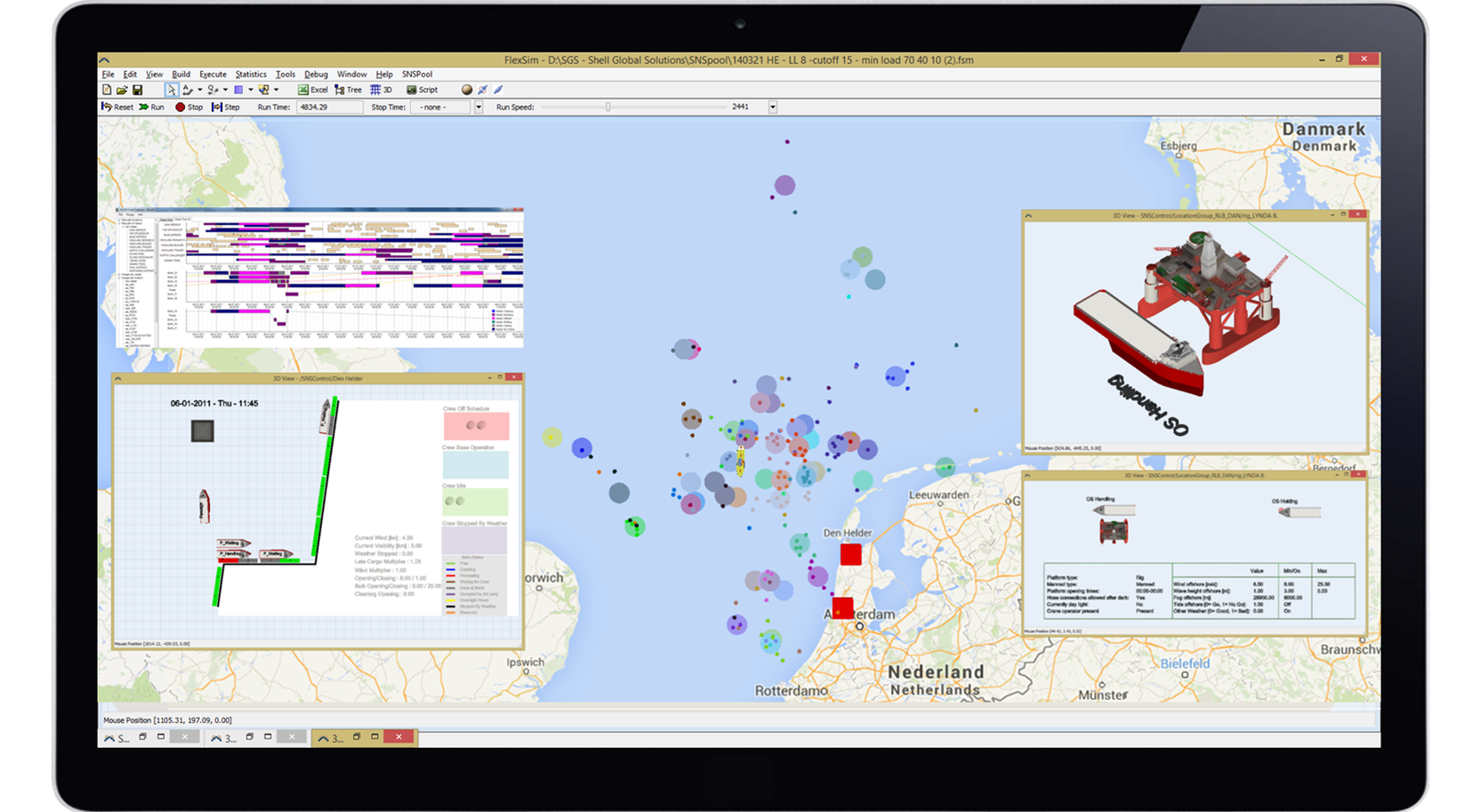

SNS-Pool

For the planning of supply vessels Talumis also created a simulation support planning system. The problem of vessel supply can be characterized as a so called “multiple vehicle routing problem with time windows”. There are mathematical optimizers that can calculate the ‘optimal’ solution. The downside is that these optimizers are very calculation intensive, cannot cope with all constraints and can only be used deterministic. Talumis created a combination of heuristics and optimization together with a very detailed simulation model. The simulation, together with the bespoke optimizer, is able to create detailed delivery plans that can be used both strategically (how many vessels do I need) as well as in operations (what is the plan for tomorrow).

Typical issues that can be tackled by Simulation supported planning and scheduling

- Test and optimize mathematical models and heuristic rules

- Automatically create robust schedules

- Prove that plans and schedules are valid

- Create more revenue

- Create better plans and schedules that require little operator interaction or improvements

- Quantify risks and predict deliver reliability